- Home

- >

- Products

- >

- Stack Mould

- >

Stack Mould

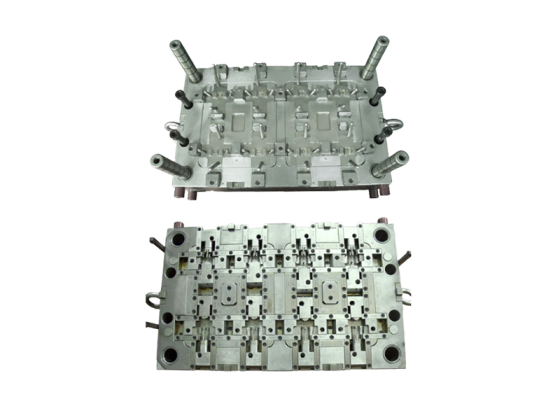

Double stack mould is used for mass production products, such as bottle caps,housing and so on Stack mould structure: 1.stack mold pouring system The stack mould hot runner system can transport injection molding raw materials to each layer parting surface, and the needle valve nozzle can be selected to control the balanced filling of raw materials according to the need. The main nozzle splitting technique divides the main nozzle into two segments, one segment is fixed on the diverter plate and the other segment is fixed on the fixed template. MOLDFLOW software is used to optimize and guide the design and manufacture of pouring system. 2.Core difficulty of pouring system The ordinary main nozzle must leave the nozzle of the injection molding machine every time and there is a relative motion with the front mold part. The main nozzle splitting technology must be used to divide the main nozzle into two parts, one part is fixed on the front template, the other part is fixed on the hot runner plate. This novel technology is an extension of the needle valve nozzle technology. The main nozzle is segmented by two opposite needle valves 3.Synchronous open mode control system In order to make the shrinkage of the plastic parts consistent, the residence time of the plastic parts in each cavity is equivalent, the precision gear and rack transmission synchronization mechanism and the rotating screw transmission synchronization mechanism are used to ensure that the parting surface of each layer of the cavity is opened at the same time. 4.Rack and pinion drive synchronous mechanism Adopt precision gear mold opening control mechanism, and optimize and improve, design and manufacture two kinds of pinion and rack transmission mechanism and rotary screw transmission mechanism of the same size to facilitate mold synchronous opening, precision control mold opening distance. 5.Load-bearing guide system Adopt "machine" type hanging guide mechanism and support mechanism, and optimize and improve, adopt high wear-resistant material design at the bottom of the guide device, greatly improve the stability of the mold and the life of the mold.