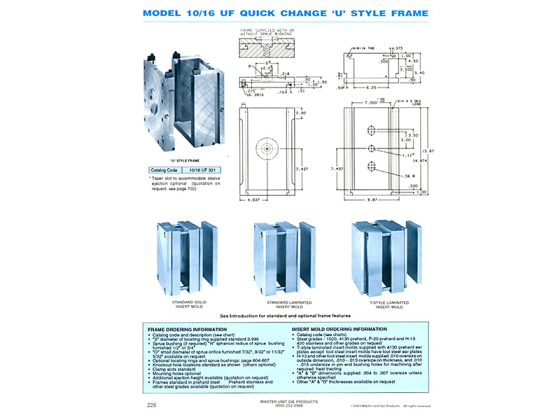

MUD Mold

MUD mold interchange mold base, fast production and improve efficiency. MUD was originally adopted in countries in North America, primarily the United States, Canada, and Colombia.MUD quick-change mold stands enable faster injection product production conversion and lower mold costs. The method of the MUD mold rapid change system is based on a mold holder that can quickly change an unlimited number of molds on the injection machine. The mold frame is fixed on the injection machine for a long time without disassembly. Most mold changes take less than five minutes, do not require special equipment, and can be operated by one person. Simply loosen the four clamps, disconnect any heating or cooling waterways, and slide in the mold from the mold to quickly change the mold holder. Then the new mold is replaced and inserted, the cooling water is reconnected, and the new insert mold is clamped ready for production. This approach reduces downtime by up to 75 percent. The associated labor costs are reduced even more because a second person is no longer needed to assist in changing the mold. The initial cost of the new mold was also reduced by 66 percent. This is because only a matching insert cavity and core need to be re-produced.