News

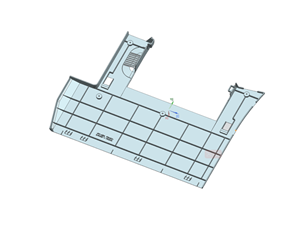

Part name: Network host controller panel Material: ABS+PC Mould type: 1Cavity number Cavity&Core: 1.2718H Mould base: LKM Cold runner: Point gate Tolerance 0.5mm Nitrogen assisted injection molding

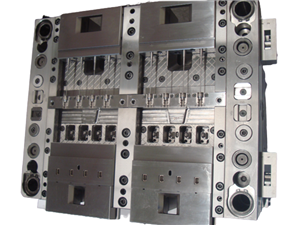

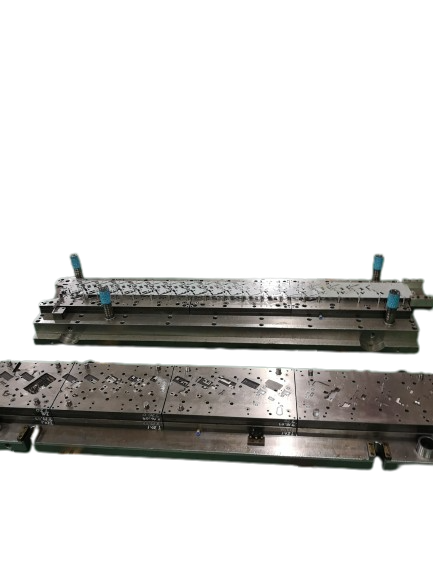

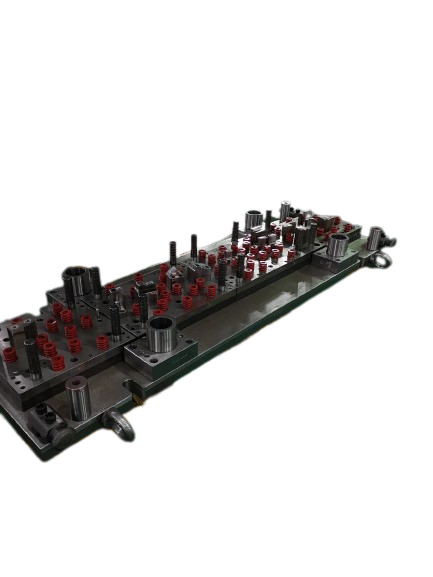

Progressive die+Hand transfer die 3D/2D drawings Layout design drawing DFM/analysis report Stamping die design Feeder specifications Processing analysis by numerical simulation(NS) of deep drawing step in progressive die(DDSPD) quickly and accurately was very important. Material:STEEL V-1140 ALT ASTM A366/A620 STD 111,401 T3~8 +0.2/-0.2MM

Precision Medical Infusion Needle Manufacturing Specifications Component Overview Part Name: Medical Infusion Needle (Class II Medical Device) Primary Material: PP 9074MED (USP Class VI Certified) Wall Thickness: 0.7mm ±0.03mm (Critical Flow Path Sections) Surface Finish: SPI-A2 (Ra ≤ 0.025μm for Fluid Contact Surfaces)

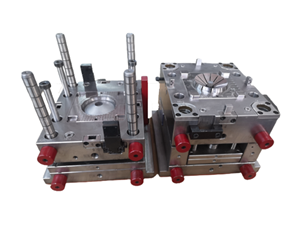

High-Precision Injection Molding for Electric Vehicle Battery Storage Components Part Name: Electric Vehicle Battery Storage Material: PA66 (BASELL) – High-temperature, flame-retardant nylon for superior mechanical and thermal stability Mold Type: Insert Molding / Injection Molding (Multi-Cavity Production) Cavity & Core: H13 Tool Steel (Hardened to 48-52 HRC for extended mold life) Mold Base: LKM Standard (DME-compatible for global serviceability) Hot Runner System: Moldmaster 4-Point Hot Nozzle (Precision temperature control for consistent fill) Tolerance: ±0.2mm (Critical for battery sealing surfaces)

Sports Equipment Zine Alloy Die Casting Die casting is a manufacturing process in which molten metal is injected into a steel mold, known as a die, under high pressure. The molten metal fills the mold cavity and solidifies, taking the shape of the mold. This process allows for the production of complex shapes with high precision and consistency Zine Alloy Die Casting mold

Part name:Spare parts for medical accessory equipment Material:ABS+PC Mould type: Family mould Cavity&Core: S136 Mould base: LKM Cold runner:Sub-gate Tolerance 0.005mm Used in hospital infusion,blood pressure,sputum suction, fluoroscopy equipment accessory parts.

Understanding the mechanics of punching stretching mould forming is crucial for anyone involved in sheet metal forming, a process vital in numerous industries, from automotive manufacturing to consumer electronics. This process, characterized by its ability to create complex three-dimensional shapes from flat sheet metal, relies on a sophisticated interplay of forces and material behavior. This article delves into the intricacies of this process, examining the underlying mechanics that govern its success and limitations. Understanding these mechanics allows for optimized process parameters, improved product quality, and reduced material waste.

The relentless pursuit of higher production rates, improved product quality, and reduced manufacturing costs drives continuous innovation in the metal forming industry. Punching and stretching, crucial processes in producing complex sheet metal parts for automotive, electronics, and appliance sectors, rely heavily on the performance and efficiency of their dedicated molds. Optimizing these molds is not just about increasing throughput; it's about achieving a delicate balance between speed, precision, and tool longevity, ultimately contributing to significant cost savings and enhanced competitiveness. This exploration delves into the multifaceted strategies for maximizing the performance and efficiency of punching and stretching molds.

Aluminum extrusion profiles have become ubiquitous in modern construction, manufacturing, and transportation, owing to their superior strength-to-weight ratio and exceptional design flexibility. This versatility stems from a manufacturing process that allows for complex shapes and intricate designs to be created with remarkable precision. Understanding the strengths and design capabilities of aluminum extrusions is key to harnessing their potential across diverse applications. From the sleek lines of a modern skyscraper to the robust framework of a heavy-duty truck, aluminum extrusions are quietly revolutionizing how we build and engineer. This exploration delves into the reasons behind their dominance and highlights the key features that make them stand out.

Discover Versatile Aluminum Extrusion Profiles: Endless OptionsAluminum extrusion profiles have become indispensable components in countless industries, from construction and automotive to aerospace and consumer electronics. Their versatility stems from the ability to create complex shapes and profiles with exceptional precision, offering a nearly endless array of possibilities for design and application. This exploration delves into the multifaceted world of aluminum extrusion profiles, highlighting the diverse options available and the reasons behind their widespread adoption.