- Home

- >

- News

- >

- Industry News

- >

News

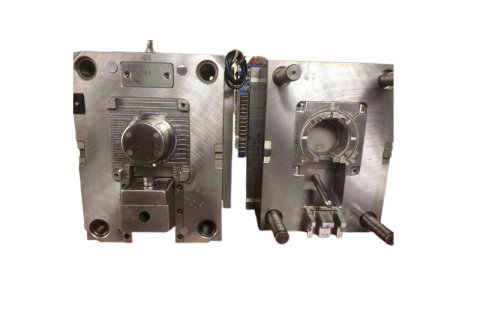

Understanding the mechanics of punching stretching mould forming is crucial for anyone involved in sheet metal forming, a process vital in numerous industries, from automotive manufacturing to consumer electronics. This process, characterized by its ability to create complex three-dimensional shapes from flat sheet metal, relies on a sophisticated interplay of forces and material behavior. This article delves into the intricacies of this process, examining the underlying mechanics that govern its success and limitations. Understanding these mechanics allows for optimized process parameters, improved product quality, and reduced material waste.

The relentless pursuit of higher production rates, improved product quality, and reduced manufacturing costs drives continuous innovation in the metal forming industry. Punching and stretching, crucial processes in producing complex sheet metal parts for automotive, electronics, and appliance sectors, rely heavily on the performance and efficiency of their dedicated molds. Optimizing these molds is not just about increasing throughput; it's about achieving a delicate balance between speed, precision, and tool longevity, ultimately contributing to significant cost savings and enhanced competitiveness. This exploration delves into the multifaceted strategies for maximizing the performance and efficiency of punching and stretching molds.

Aluminum extrusion profiles have become ubiquitous in modern construction, manufacturing, and transportation, owing to their superior strength-to-weight ratio and exceptional design flexibility. This versatility stems from a manufacturing process that allows for complex shapes and intricate designs to be created with remarkable precision. Understanding the strengths and design capabilities of aluminum extrusions is key to harnessing their potential across diverse applications. From the sleek lines of a modern skyscraper to the robust framework of a heavy-duty truck, aluminum extrusions are quietly revolutionizing how we build and engineer. This exploration delves into the reasons behind their dominance and highlights the key features that make them stand out.

Discover Versatile Aluminum Extrusion Profiles: Endless OptionsAluminum extrusion profiles have become indispensable components in countless industries, from construction and automotive to aerospace and consumer electronics. Their versatility stems from the ability to create complex shapes and profiles with exceptional precision, offering a nearly endless array of possibilities for design and application. This exploration delves into the multifaceted world of aluminum extrusion profiles, highlighting the diverse options available and the reasons behind their widespread adoption.

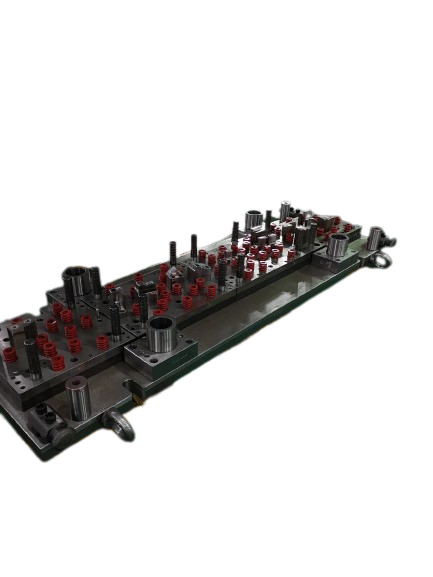

Advanced punching and shearing die design is a critical aspect of modern manufacturing, impacting product quality, production efficiency, and overall profitability. This intricate process involves creating specialized tooling to precisely cut and form sheet metal components, ranging from simple shapes to highly complex geometries. Understanding advanced techniques in this field is crucial for engineers and designers seeking to optimize their manufacturing processes and achieve superior results. This article delves into several key aspects of advanced punching and shearing die design, highlighting innovative strategies and considerations for optimal performance.

The relentless pursuit of efficiency and precision in manufacturing has driven significant innovation in the field of punching and shearing dies. These fundamental tools, used to cut and shape sheet metal, are undergoing a transformation, moving beyond traditional designs to incorporate advanced materials, geometries, and manufacturing processes. This evolution is crucial for industries ranging from automotive and aerospace to electronics and construction, where the demand for higher production rates, improved part quality, and reduced costs is constantly increasing. This exploration delves into innovative solutions reshaping the landscape of punching and shearing die technology, examining advancements that are not only enhancing performance but also promoting sustainability and flexibility.

High-precision punching and shearing die manufacturing is a critical process in numerous industries, ranging from automotive and aerospace to electronics and medical devices. These dies, sophisticated tools used in stamping processes, are responsible for creating intricate shapes and precise cuts in sheet metal with exceptional accuracy. The demand for smaller, lighter, and more complex components has driven a relentless pursuit of higher precision in die manufacturing, pushing the boundaries of engineering and manufacturing technology. The intricate nature of these dies, demanding tolerances measured in microns, highlights the specialized expertise and advanced machinery required for their creation. This exploration delves into the intricacies of high-precision punching and shearing die manufacturing, shedding light on the key aspects that contribute to its precision and efficiency.

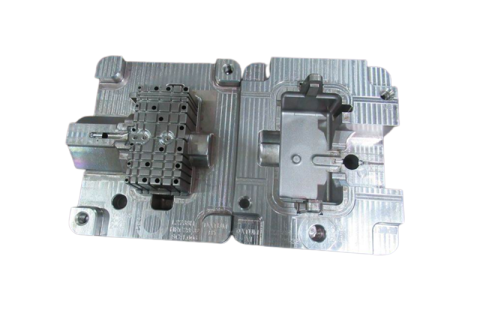

Punching and shearing dies are fundamental tools in sheet metal fabrication, used to create precise holes and cut shapes from metal sheets. Their efficiency and longevity directly impact production costs and overall manufacturing success. Optimizing their performance, therefore, is crucial for any manufacturer striving for competitiveness. This involves a multifaceted approach encompassing material selection, die design, and operational practices. Understanding these elements allows for the creation of robust, productive, and cost-effective punching and shearing processes. This exploration will delve into the key strategies for optimizing the performance of these vital tools.

The world of manufacturing is constantly evolving, driven by the relentless pursuit of efficiency, precision, and cost-effectiveness. At the heart of many manufacturing processes lies the humble, yet crucial, punching and shearing die. These seemingly simple tools are responsible for shaping countless products we use daily, from automotive parts and electronic components to intricate medical devices. Recent advancements in die technology have significantly impacted the industry, unlocking new levels of performance and capability. This exploration dives into the latest innovations shaping the future of punching and shearing die technology.

Cost-effective manufacturing is paramount in today's competitive industrial landscape. For businesses relying on sheet metal fabrication, the design and implementation of punching and shearing dies play a crucial role in determining overall production efficiency and profitability. High-quality, yet affordable, punching and shearing die solutions are no longer a luxury; they're a necessity for maintaining a competitive edge. This exploration delves into various strategies and considerations for achieving cost-effective punching and shearing die solutions, highlighting the balance between initial investment, long-term performance, and overall return on investment (ROI).

Punching and shearing dies are crucial components in numerous manufacturing processes, playing a vital role in shaping sheet metal into a vast array of products. From automotive parts and electronics to appliances and construction materials, these dies are essential for creating precise cuts and shapes with high speed and accuracy. However, the effectiveness of any manufacturing process hinges significantly on the durability and efficiency of its tooling. This article delves into the critical factors influencing the lifespan and productivity of punching and shearing dies, examining the materials, design considerations, and operational practices that contribute to optimal performance. Understanding these aspects is key to minimizing downtime, reducing costs, and maintaining consistent product quality.

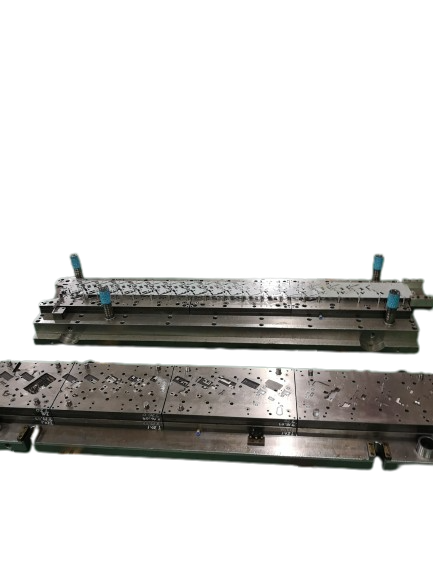

Mastering the art of progressive die strip layout is crucial for efficient and cost-effective metal stamping. This seemingly intricate process, often overlooked, significantly impacts production speed, material usage, and overall profitability. For those involved in metal stamping, from design engineers to production managers, a deep understanding of progressive die strip layout techniques is paramount. This exploration delves into the key aspects of mastering this critical skill, offering insights that can significantly improve efficiency and reduce waste in your stamping operations. Think of it as the choreography of metal forming—a well-planned layout ensures a smooth, efficient dance of metal transformation, while a poorly planned one results in a chaotic, wasteful performance.